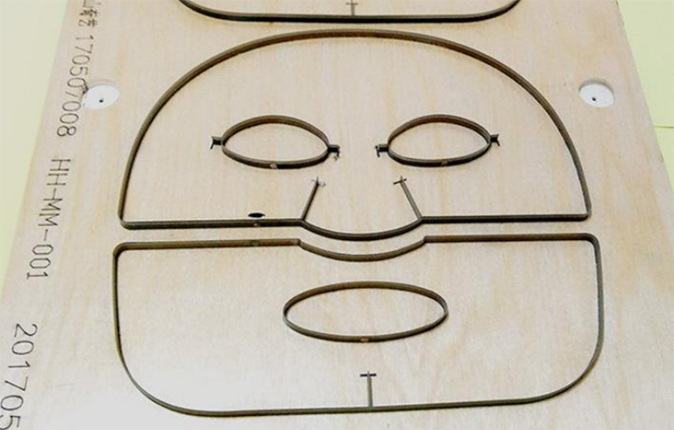

The laser knife mould

The laser knife mold is a die-cutting shape mold. The use method is stamping. The structure is normally composed of a base plate and a steel blade. The base plate is usually an 18mm multi-layer wood board. Acrylic and plastic boards can also be used instead.

Production process:

The main consumables for making laser knife molds are the knife templates. The knife templates are mainly plywood. The tree species normally used for knife templates are mainly poplar, birch, and basswood. Whether the quality of the knife template is stable or not directly affects the production effect of the laser knife mold.

The roller knife mould

The roller knife mould production process:

1. According to the drawings, computer drawing design

2. Select the steel with the corresponding diameter according to the product

3. CNC machining, using special CNC machine tools to process molds, takes a long time

4. Quenching

5. Sharpening the blade, this step cannot be done by machine, it needs to be done manually by an experienced master, and the requirements are high.

After introducing the production process of the two types of knife moulds, let’s talk about the advantages and disadvantages of the two.

The laser knife mould

Advantages:

cheap, simple and fast manufacturing process.

Disadvantages:

1. Poor accuracy, it is easy to cut through the lowest layer of film when producing or proofing half-cut products.

2. The service life is low. The cutter is made by inserting the blade into the wooden board. If the number of production or proofing is too many, the laser knife mould will not be cut easily, which will affect the quality of the product.

The roller knife mould

Advantages:

1. It can cut products quickly, improve work efficiency, and meet the needs of large-scale production.

2. Long lifespan. According to our experience, we can produce about 30,000 to 500,000 patches by using a roller knife mould for die cutting.

Disadvantages:

1. Since CNC machining is required to produce a set of roller knife mould, it takes a long time to queue up and take a long time to consider the use of machines, so it takes at least 2 weeks to produce a set of roller knife mould.

2. The price is expensive: an average mold needs 1000-2000USD.

Therefore, our suggestion is to use the laser knife mould in the sample stage and the roller knife mould in mass production.

Post time: Dec-08-2021